| Sign In | Join Free | My carsrow.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My carsrow.com |

|

Brand Name : YIZGEAR

Place of Origin : CHINA

MOQ : 2 Sets

Payment Terms : L/C, T/T

Supply Ability : 500 Sets/Month

Delivery Time : 35 Days

Packaging Details : Plywood Crate

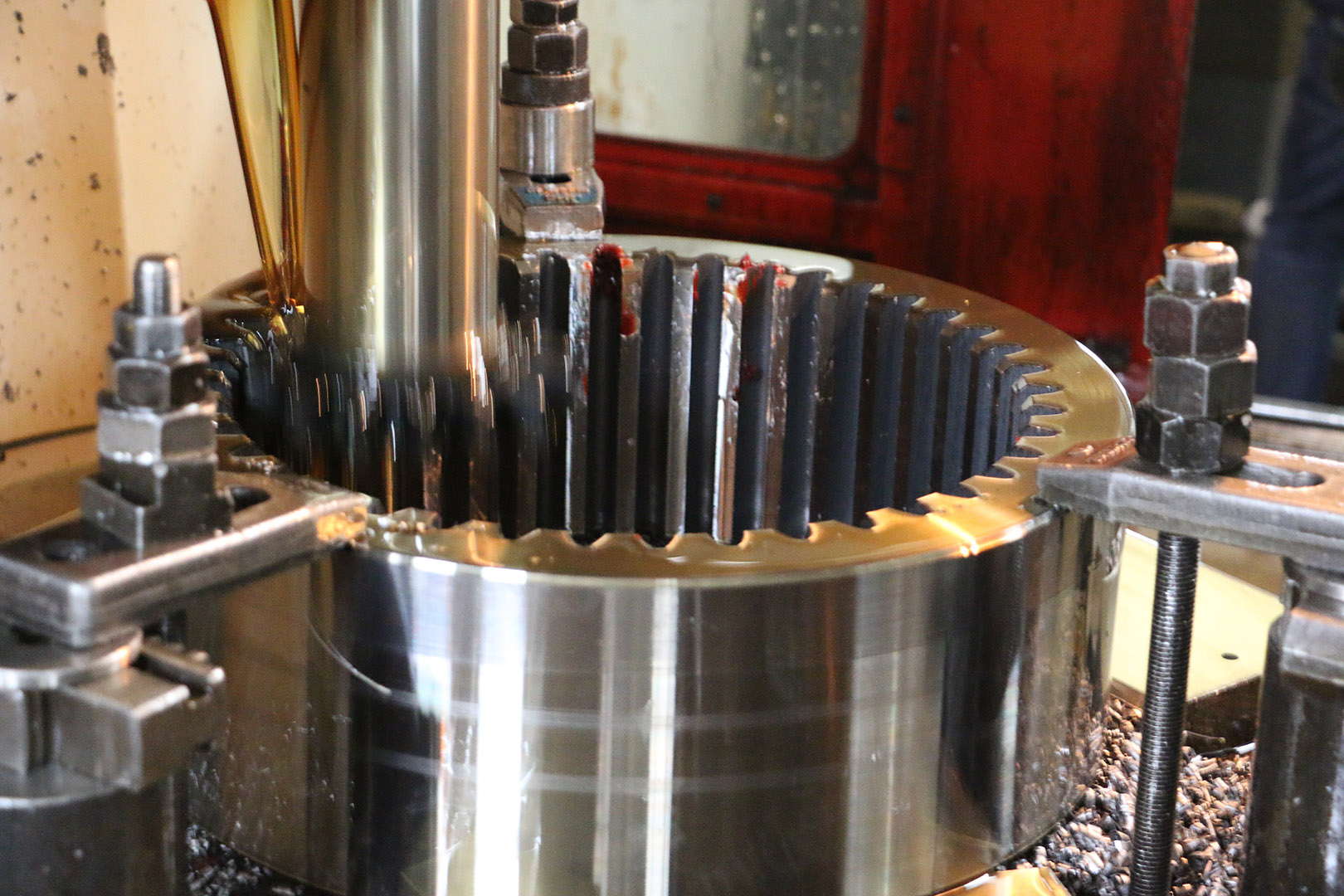

Type : Cylindrical Gear

Gear Profile : Internal Gear

Manufacturing Method : Machining/Gear Shaping

Heat Treatment : Quenching & Tempering

Material : Steel

Production Time : 35 Days

| Parameter | Specification |

|---|---|

| Custom Made | Available |

| Gear Profile Type | Cylindrical Gear |

| Manufacturing Process | Gear Milling & Gear Teeth Hobbing |

| Teeth Grinding | Included |

| Module (M) | 0.5-25 |

| Number of Teeth (Z) | Custom |

| Pressure Angle (α) | Custom |

| Lead Angle | Custom |

| Accuracy Grade | ISO 8-9 Grade |

| Heat Treatment | Nitriding |

| Surface Hardness | 650HV |

| CHINA/GB | ISO | ГΟСТ | ASTM | JIS | DIN |

|---|---|---|---|---|---|

| 45 | C45E4 | 45 | 1045 | S45C | CK45 |

| 40Cr | 41Cr4 | 40X | 5140 | SCr440 | 41Cr4 |

| 20CrMo | 18CrMo4 | 20ХМ | 4118 | SCM22 | 25CrMo4 |

| 42CrMo | 42CrMo4 | 38XM | 4140 | SCM440 | 42CrMo4 |

| 20CrMnTi | 18XГT | SMK22 | |||

| 20Cr2Ni4 | 20X2H4A | ||||

| 20CrNiMo | 20CrNiMo2 | 20XHM | 8720 | SNCM220 | 21NiCrMo2 |

| 40CrNiMoA | 40XH2MA/40XHMA | 4340 | SNCM439 | 40NiCrMo6/36NiCrMo4 | |

| 20CrNi2Mo | 20NiCrMo7 | 20XH2MA | 4320 | SNCM420 |

|

|

Custom Internal Spur Gear with Gear Milling and Hobbing for High-Efficiency Equipment Images |